Journal of Applied Sciences and Applications in Engineering

Review Article Volume: 1 & Issue: 1

Review Article Volume: 1 & Issue: 1

Solar energy technologies have advanced significantly, transforming the way we harness sunlight into electricity. Photovoltaic (PV) systems and concentrated solar power (CSP) are two primary methods that have gained prominence. PV systems convert sunlight directly into electricity using semiconducting materials, while CSP systems use mirrors or lenses to focus sunlight, generating heat that drives turbines. These advancements aim to increase efficiency, reduce costs, and promote sustainable energy production. This review explored the advances in solar energy technologies with emphasis on photovoltaic systems and concentrated solar power. Findings from this study revealed that recent breakthroughs in solar energy technologies have led to improved efficiency and affordability. Perovskite solar cells have shown remarkable efficiency rates above 30%, while tandem solar cells can capture a wider range of sunlight, boosting efficiency. Bifacial solar panels generate energy from both sides, increasing output. Smart solar panels with IoT connectivity optimize energy production and predict maintenance needs. Advancements in energy storage, such as lithium-ion batteries, enable efficient utilization of stored solar energy. These innovations are driving the adoption of solar energy across residential, commercial, and utility-scale projects. Advances in solar energy technologies have transformed the industry, offering improved efficiency, affordability, and sustainability. Innovations in PV systems, CSP, and energy storage have made solar energy a viable option for various applications. As research continues, solar energy is poised to play a crucial role in the global transition to renewable energy.

Keywords: Photovoltaic systems, Solar energy, Power, Efficiency, and Renewable energy.

Global energy demand continues its upward trajectory, driven by population growth, urbanization, and accelerating industrial development, placing unprecedented strain on conventional energy systems.1 Despite rapid deployment of photovoltaic and wind power, renewables accounted for only 26 percent of global electricity generation in 2018, falling well short of levels required to meet international climate targets.2 Moreover, solar and wind collectively contributed merely 10 percent of worldwide power output in 2020, underscoring the need to diversify clean-energy portfolios beyond variable sources and to integrate dispatchable renewables into modern grids. In this context, deep decarbonization hinges not only on the expansion of renewables but also on technologies that can store energy at scale, enhance grid flexibility, and deliver reliable baseload and peak power.

Concentrated solar power (CSP) offers a compelling pathway to meet these imperatives by using optical concentrators such as parabolic troughs, linear Fresnel systems, and solar towers to capture direct normal irradiance and convert it into high-temperature thermal energy.4 Unlike photovoltaic systems that produce electricity instantaneously, CSP plants channel heat into storage media (for example, molten salts or phase-change materials), enabling multi-hour dispatchability without fossil-fuel backup. Recent advances have pushed operating temperatures above 600 °C, improved heat-transfer fluids, and optimized receiver designs, which together have elevated thermal-to-electric efficiencies and driven down levelized costs of electricity.

Thermal energy storage is the lynchpin of CSP’s value proposition, smoothing output fluctuations and shifting generation into evening peaks when demand is highest. Integrated storage systems now routinely offer six to fifteen hours of autonomous operation at marginal costs competitive with conventional gas-fired peakers, reducing solar curtailment and enhancing revenue stream.6 Hybrid configurations pairing CSP with biomass, geothermal inputs, or supercritical CO₂ cycles further bolster reliability and overall plant efficiency, while mitigating the geographic constraints of purely solar installations.7 Despite these breakthroughs, critical research gaps remain in materials durability, dynamic performance modeling under real-world conditions, and cost-effective scale-up strategies.8 Addressing these challenges through targeted R&D, advanced simulation tools, and pilot demonstrations will be essential to unlock CSP’s full potential in high-irradiance regions. Hence, this review delineates recent technological advancements in CSP focusing on optical concentrator architectures, thermal energy storage innovations, and hybridization strategies to chart a roadmap for improving system performance, reliability, and economic viability, thereby informing future deployment and research priorities.

Photovoltaic (PV) Systems

First to fourth Generation PV (silicon, thin film, perovskite)

Global energy systems are increasingly reliant on photovoltaic (PV) technologies to meet rising electricity demand while curbing greenhouse gas emissions. Since the advent of the first generation of PV, crystalline silicon (c Si) wafers have dominated the market, with cell efficiencies climbing from roughly 6 percent in the 1950s to commercial module averages of 20–22 percent and laboratory records now exceeding 27 percent under standard test conditions.9

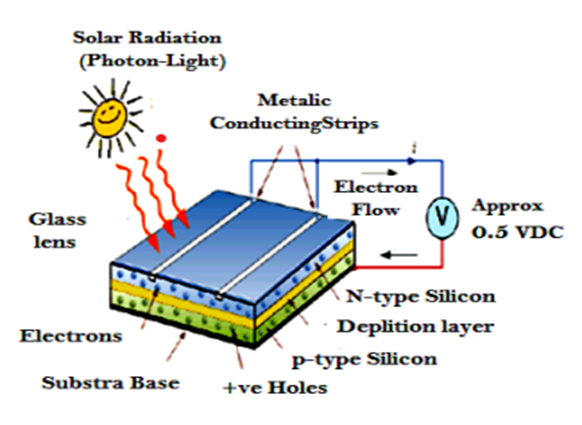

The basic operating principle that underpins these advances is shown in Figure 1: incoming solar radiation (photons) passes through the protective glass and is absorbed in the semiconductor stack, generating electron–hole pairs at the p–n junction; the built in electric field across the depletion region separates these carriers, driving electrons toward the n type side and holes toward the p type side, where metallic conducting strips collect charge and deliver a DC voltage (approximately 0.5 V per silicon cell under typical illumination) for external use. This cell level physics of light absorption, carrier generation, separation, and collection is the foundational mechanism reproduced across generations of PV devices and scaled in practice by interconnecting cells into modules and arrays for grid or off grid applications.10Table 1. Comparison of PV technologies

| Technology (Materials) | Generation | Typical Module Efficiency | Laboratory Record Efficiency | Key Advantages | Key Challenges |

| Crystalline Silicon | First | 20–22% | >27% | Mature supply chain; high reliability | High material cost; energy-intensive process |

| Thin-Film (CdTe; CIGS; a-Si) | Second | 12–18% | ~23% | Low cost; lightweight; flexible | Lower efficiency; potential material toxicity |

| Perovskite | Third | Commercial nascent | >25% | Low-temperature fabrication; tunable | Stability issues; scale-up challenges |

| Multi-Junction Tandem (Si; III–V) | Fourth | Commercial nascent | >31% | Highest efficiencies; spectrum splitting | Complex manufacturing; high fabrication cost |

Source: Lazaroiu et al.9

Second generation thin film PV encompassing cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon emerged in the late twentieth century offering lower manufacturing costs and flexible form factors, with typical module efficiencies settling in the 12–18 percent range and laboratory peaks approaching 23 percent.11 Table 1 compares these PV technologies, highlighting the trade offs between mature silicon platforms and lower cost thin films. Building directly on the cell architecture illustrated in Figure 1, third generation PV has risen rapidly over the past decade, led by metal halide perovskite solar cells that combine solution processable fabrication with high optoelectronic quality; perovskite devices leverage the same photon to carrier conversion but with higher absorption coefficients and tunable bandgaps, enabling single junction efficiencies to climb from about 3 percent in 2009 to over 25 percent while research continues to address stability and scale up challenges.12 Fourth generation architectures extend the same device physics through tandem and multi junction stacking pairing perovskite or III–V absorbers with silicon or other sub cells to capture distinct portions of the solar spectrum and reduce thermalization losses producing laboratory records above 31 percent and pointing the way toward next generation high performance systems.13

Figure 1. Structure of a PV cell

Source: National Renewable Energy Laboratory11

Concentrated Solar Power (CSP)

Concentrated solar power (CSP) encompasses three mature collector architectures parabolic troughs, central receiver (power towers), and linear Fresnel systems each optimized for different temperature regimes, cost profiles, and siting conditions.12 Parabolic troughs use curved, single axis trackers that heat a flowing heat transfer fluid (typically synthetic oil or molten salt) to roughly 400 °C and remain the most deployed CSP technology due to modular solar field economics and proven steam Rankine integration.13 Power towers employ dual axis heliostats to focus sunlight onto a receiver atop a tower, enabling much higher receiver temperatures (well above 600 °C) that unlock higher efficiency cycles (including supercritical CO₂) and broaden storage media options, but they require advanced heliostat control and more complex receiver engineering Linear Fresnel systems simplify the mirror geometry to lower capital cost and maintenance complexity, typically reach lower peak temperatures (≈300–350 °C), and can be competitive where simpler construction and land packing advantages matter.14

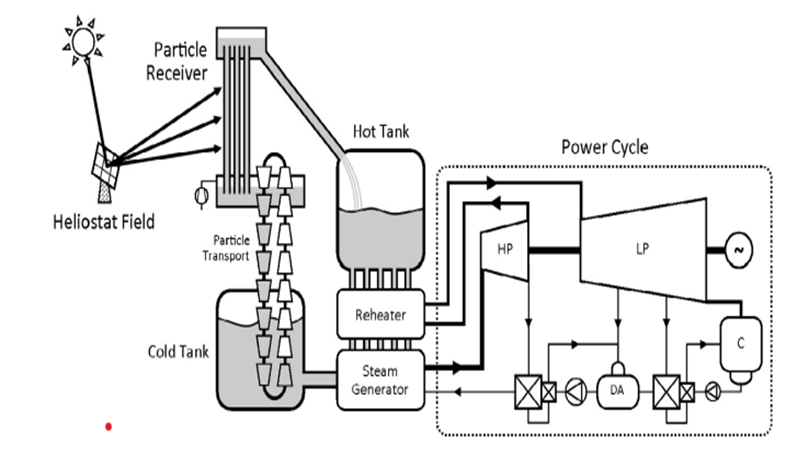

The particle based schematic shown in the figure complements these architectures by illustrating a power tower configuration that uses solid particles as the heat transfer and storage medium. A heliostat field reflects concentrated sunlight onto a particle receiver atop the tower, where flowing particles are heated to very high temperatures.1 The heated particles are routed to a hot tank for storage, while cooled particles return to a cold tank via the particle transport system; when electricity is required, hot particles supply thermal energy to a steam generator and reheater, driving an HP turbine and then an LP turbine in a Rankine power cycle with downstream deaerator and condenser components that complete the steam loop and feed the pump and generator.3 This particle based approach extends the operational temperature window beyond conventional molten salts, increases volumetric storage density, reduces freeze point constraints, and can simplify high temperature receiver design benefits that directly address several limits of liquid based TES and enable greater flexibility in plant operation and hybridization.5

Parabolic Trough, Power Tower, Fresnel

Particle based receivers and packed bed storage are an active research pathway for next generation towers: solid particles circulated through a receiver can attain very high temperatures (>700 °C in demonstrations), increase volumetric storage density, avoid molten salt freeze issues, and enable higher efficiency power cycles; pilot and experimental demonstrations have validated the basic particle receiver concept and quantified operational challenges such as entrained air heat losses and particle handling design.6 Across architectures, the defining strength of CSP is its native compatibility with thermal energy storage (TES): two tank molten salt systems and alternative packed bed or phase change approaches allow multi hour dispatch, shifting generation to evening peaks and improving capacity factors in high DNI sites. For techno economic context, recent reviews and programmatic reports synthesize performance, storage integration, and cost trajectories for troughs, towers, and Fresnel systems and for emerging particle based receivers, supporting continued R&D and deployment where direct normal irradiance and utility scale needs favor dispatchable solar power.7

Figure 2. CSP plant layout

Source: Spelling et al.7

Comparative Analysis of Photovoltaic (PV) and Concentrated Solar Power (CSP)

Global deployment of solar energy has surged in recent years as nations strive to decarbonize electricity systems, yet PV and CSP technologies exhibit distinct attributes that influence their suitability, cost structure, and integration pathways.8 PV systems, from first-generation crystalline silicon to emerging multi-junction tandems, directly convert sunlight into electricity with module efficiencies ranging from 20 to 22 percent in commercial installations and laboratory records exceeding 27 percent under standard conditions.9 In contrast, CSP plants harness direct normal irradiance using optical concentrators parabolic troughs, power towers, or linear Fresnel arrays to generate high-temperature heat, driving thermal cycles with typical thermal-to-electric efficiencies between 15 and 20 percent for trough systems and up to 23 percent in power towers operating above 600 °C.10

Efficiency, Cost, and Storage

Cost trajectories further differentiate these technologies. Utility-scale PV LCOEs have plummeted to as low as $0.03–0.05 per kWh, fueled by economies of scale, streamlined manufacturing, and simplified balance-of-system components.11 By contrast, CSP projects with integrated molten-salt storage generally exhibit LCOEs in the range of $0.10–0.12 per kWh owing to higher capital expenditure on optics, receivers, and thermal storage infrastructure.12 However, CSP’s inherent thermal energy storage (TES) capability typically 6–15 hours of dispatchable output at round-trip efficiencies above 98 percent enables firm, on-demand generation without reliance on battery systems, whereas PV facilities must pair with battery-energy storage systems that can add significant cost and complexity.13

Geographic Suitability

Geographic and climatic factors strongly influence technology selection and reinforce the practical pros and cons summarized in Table 2. PV panels can operate under global horizontal irradiance levels above 1,200 kWh/m2/year, tolerate diffuse sunlight and a wide temperature range, and thus are deployable across temperate to tropical regions where their low capital cost, modular deployment, and high module efficiency make them attractive for rapid rollout and diverse applications such as rooftops, agrivoltaics, and floating arrays.14 These advantages also explain PV’s short project timelines and scalability from small to multi GW installations, but they come with the intermittent generation drawback that typically requires battery storage or grid flexibility measures to provide firm capacity. In contrast, CSP demands high direct normal irradiance typically greater than 2,000 kWh/m2/year so economically viable deployments are largely restricted to desert and arid zones with minimal cloud cover and low atmospheric water vapor.1 The CSP pros of built in thermal storage, dispatchable power, and provision of high temperature process heat fit well with utility scale sites that can accommodate CSP’s larger land footprint and longer development timelines, yet these same characteristics produce higher capital cost and siting constraints, including water needs for steam cycles and minimum viable plant sizes.4 Consequently, CSP finds its niche where grid operators value firm, on demand generation and industrial heat, while PV dominates where rapid, low cost capacity addition and flexible siting are priorities; hybrid PV–CSP configurations can combine PV’s low cost daytime output with CSP’s storage and dispatchability to optimize land use, reduce overall LCOE, and deliver more stable capacity factors.4,5,6

Table 2. PV vs CSP Pros and Cons

| Technology | Pros | Cons |

| PV | Low capital cost; modular deployment; high module efficiency | Intermittent generation; requires battery storage; performance drop at high temperatures |

| CSP | Built-in thermal storage; dispatchable power; high-temperature heat | High capital cost; geographic constraints; long development timelines |

Source: Xu and Li13

Recent Advances and Innovations

Recent efforts to push photovoltaic performance beyond conventional limits have centered on tandem solar cells and bifacial modules, while hybrid PV–CSP systems are emerging to marry the strengths of both technologies. In the realm of tandem devices, metal halide perovskite layers stacked atop crystalline silicon substrates have garnered particular attention. Ehsan4 reported that by engineering the interface between a 1.68 eV perovskite absorber and an n-type silicon heterojunction bottom cell, they achieved a certified power-conversion efficiency of 28.1 percent in a two-terminal configuration. Critical to this advance was the introduction of a self-assembled monolayer that simultaneously reduces non-radiative recombination at the perovskite/transport-layer interface and enhances stability under continuous illumination, extending operational lifetimes beyond 1,000 hours at maximum power point.6 These findings underscore how targeted materials and surface-chemistry innovations can bridge the efficiency gap between laboratory champions and large-area modules.

Tandem solar cells, bifacial panels.

Parallel to tandem breakthroughs, bifacial silicon modules have transitioned from niche applications into mainstream deployment. Xu and Li13 demonstrated that next-generation passivated emitter and rear cell (PERC) architectures can be optimized for bifacial operation by adjusting rear-surface field dopant profiles and applying high-reflectance back sheet materials. Field trials in a subtropical climate setting revealed that bifacial gains additional energy captured from albedo and ground-reflected irradiance ranged from 12 to 18 percent compared to monofacial counterparts, depending on mounting height and ground-cover reflectivity.13 Such performance improvements, coupled with only marginal increases in BOM (balance-of-materials) cost, position bifacial modules as a near-term solution for boosting yield in both utility-scale and rooftop installations.

Hybrid PV-CSP Systems

Complementing these PV-centric innovations, hybrid PV–CSP systems leverage photovoltaic arrays for daytime power and concentrated solar thermal collectors for dispatchable output. Yousef et al.14 analyze design strategies that integrate bifacial PV fields with parabolic trough loops sharing the same land footprint and grid connection. In one pilot demonstration, a 50 MW hybrid plant in a desert environment achieved a combined capacity factor of 32 percent by dynamically diverting solar field acreage between PV and CSP subsystems according to irradiance and grid-demand forecasts. Thermal storage via a two-tank molten-salt system provided six hours of guaranteed dispatch, while the PV component delivered lowest-cost peak-day electricity. Zhou and Liu conclude that hybridization can reduce LCOE by up to 15 percent relative to standalone CSP while preserving firm capacity, provided the site offers high direct normal irradiance and moderate diffuse light levels.12

Future Directions and Policy Implications

The solar energy sector is entering a phase defined by materials innovation, system integration, and digitalization that will raise both efficiency and the grid value of solar generation. In photovoltaics, perovskite–silicon tandems and other multi junction architectures are already breaking single junction limits, with verified tandem devices exceeding 32 percent power conversion efficiency in research settings and ongoing materials and interface engineering aimed at closing the gap to commercial deployment over the coming years13. Concurrently, CSP is advancing through higher temperature receivers and working fluids and by coupling with advanced power cycles (including supercritical CO₂) and two tank molten salt storage, enabling dispatchable operation and capacity factors that can exceed 50 percent at high irradiance sites. Finally, hybrid PV–CSP configurations that place low cost bifacial or conventional PV fields alongside CSP loops are showing promising techno economic synergies: PV supplies low cost daytime energy while CSP’s thermal storage provides evening dispatch and grid services, together improving land use efficiency and reducing system LCOE relative to standalone CSP or PV only solutions.14

Realizing these technological advances at scale will require policy frameworks that incentivize long-term R&D, streamline project permitting, and internalize the societal value of firm, low-carbon power. Governments should expand competitive funding for pilot demonstrations of tandem and hybrid systems, while establishing predictable feed-in tariffs or contracts for difference that reflect the dispatchability premium of stored solar energy.13

Conclusion

The confluence of advancing photovoltaic (PV) and concentrated solar power (CSP) technologies is reshaping the landscape of renewable electricity by uniting rapid cost declines with firm, dispatchable generation. First‐generation silicon and second‐generation thin‐film PV have driven module prices to record lows and enabled ubiquitous deployment, while third‐ and fourth‐generation innovations perovskite‐silicon tandems and multi-junction stacks are poised to breach 30 percent efficiency at scale. CSP systems, meanwhile, have demonstrated their unique ability to store thermal energy for six to fifteen hours with minimal losses, delivering evening and peak‐load power at capacity factors above 50 percent when sited in high‐irradiance regions. Hybrid PV–CSP plants leverage these strengths by shading parabolic trough fields with bifacial arrays during the day and shifting to stored‐heat generation after sunset, reducing levelized costs by up to 15 percent compared to standalone CSP.

Realizing the full potential of these complementary approaches will hinge on policy frameworks that reward flexibility and firm capacity, incentivize long-term R&D, and streamline permitting for integrated projects. Carbon pricing, contracts for difference that value storage dispatch, and circular-economy mandates for end-of-life recycling can align market signals with climate imperatives and supply-chain sustainability. As PV efficiencies continue to climb and CSP materials and design innovations push thermal limits beyond 650 °C, solar energy stands ready to serve as both the backbone and the stabilizer of a decarbonized grid. The strategic integration of low-cost PV, high-efficiency tandems, and dispatchable CSP thus represents a resilient and economically viable pathway toward net-zero power systems worldwide.